EXCITING NEWS!

THE SINKING OF THE WORLD'S FIRST

UNDERWATER VILLA - MURAKA

FEBRUARY 2018

For Conrad Maldives Rangali Island

This underwater villa (UWV) will become the largest

and most spectacular attraction of its type in the world.

Due for completion and official opening in November 2018, this exciting project has taken almost 2 years to design, fabricate, ship to site, install and commission.

Mike Murphy celebrating just after the UWV was sunk.

End Client: - Conrad Maldives Rangali Island

Our Direct Client: - Crown Company Pvt Ltd, Maldives

Architect: - Ahmed Saleem, Crown Co. Pvt Ltd, Maldives

Concept Designers: - Ahmed Saleem & Mike Murphy

UWV Designers / Structural Engineers: - M.J. Murphy Ltd, Auckland, NZ

Acrylic Designers: - M.J. Murphy Ltd, Auckland, NZ

Main Contractors: - Hong Hock Engineering Pte Ltd, Singapore

Barge Operators: - Hiap Shing Shipping Pte Ltd, Singapore

Project Managers: - Shenaz Trading Pte Ltd, Singapore

Acrylic Contractors: - Nippura Co, Japan

Air Conditioning Consultants: - Jackson Engineering Advisers Ltd, Auckland, NZ

Mechanical Contractors: - Aircool Refrigeration Ltd, NZ

Electrical Contractors: - Direct Control Ltd, NZ

Fire Engineers:- Origin Fire Consultants Ltd, Auckland, NZ

Interior Design: - Yuji Yamazaki, New York, USA

Plumbing & Drainage Contractors:- Plumbuilt Ltd, NZ

Piling Contractor: - Heavy Force Pvt Ltd, Maldives

Concrete Contractor: - M.T. Højgaard Ltd, Maldives

Crane Ship Operators: - Jumbo Maritime, Netherlands

New Zealand, July 2016

Working closely with architect / client Ahmed Saleem, Mike Murphy of M.J. Murphy Ltd started work on design of the revolutionary new underwater villa for Conrad Maldives.

Having already done the design of two previous underwater restaurants (including Conrad's now famed Ithaa), and being the leading experts in this field, M.J. Murphy Ltd were the obvious choice to take up the challenge.

We had never had a full personnel lift in the design before, and this was the first UW unit with plumbing and drainage below sea level.

This was to be the most complex and the largest underwater structure we had attempted. For instance, Ithaa was approx. 250 tonnes, Huravalhi UWR was 410 tonnes, and this new villa was to be around 610 tonnes!

Quite a few design options were explored, before the final option was agreed with the clients. The design principles would follow the same format and successful lifting system we adopted for our previous Huravalhi UWR.

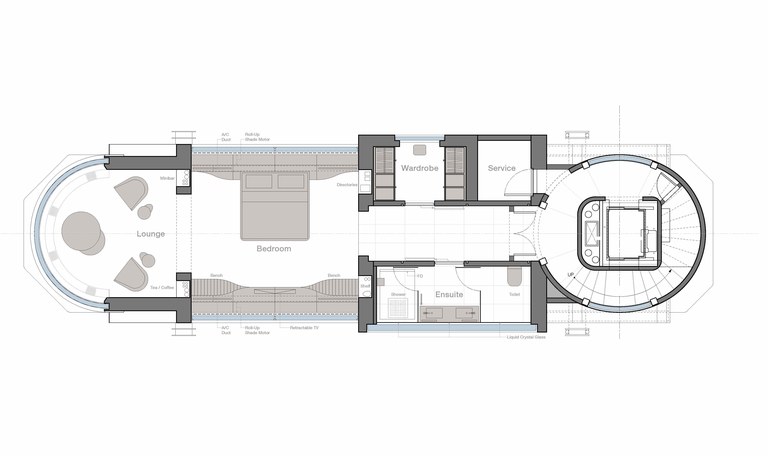

Floor plan of underwater villa

We were also able to utilise the very experienced NZ consultants we had used on the previous UWRs (refer to list), which made our work much easier with less "learning curve". Full thanks to all these clever people.

Singapore - 2017

At time of tender the winning contractors, Hong Hock Engineering, advised they would be unable to transport the completed 610 tonnes structure on the roads from their workshop to the Singapore port.

But they came up with an ingenious solution, where they could transport the UWV in 3 smaller pieces to a large barge moored at the port, and then assemble the entire structure on the barge.

In spite of some doubt for this method, in the end it proved very successful, albeit a little more complex than if it had been done on land.

Hong Hock built a temporary shelter over the entire UWV, which could be removed in sections for access as required - say to install acrylic windows.

A heavy crane was located on an adjacent barge, so it did not disturb the balance on the barge carrying the UWV.

Some painting of the steelwork was done in the workshop, with the remainder completed on the barge, under cover.

This UWV - at the client's request - also had to incorporate a second escape route, for additional fire safety, as witnessed by the second cylindrical tower.

After all painting was completed, a large quantity of concrete and sand was passed inside the UWV, to act as ballast, thus assisting in the sinking of the UWV.

This had to be carefully distributed to ensure the centre of gravity was in correct location. All ballast was added in Singapore, and carefully weighed using load cells.

Temporary shelter over UWV, and crane on adjacent barge.

Acrylic installation

As expected, the acrylic window design is all-important, and gives the wow-factor to the UWV.

The client wished to reuse our popular 5m wide acrylic arch for the bedroom (same arch as the one used for Ithaa and Huravalhi).

For the lounge, we designed a spectacular new semi-circular window, to give amazing 180° views of the coral reef. It is 135mm thick.

To avoid any visible means of support, we had to design the steel roof over the lounge as a very strong self supporting cantilever, to resist the downward water pressure.

The stairwell also has two curved windows, to give the visitors an introductory sense of descending beneath the waves.

The journey continues into the lower entry corridor, which has a 3.8m long acrylic roof window, which helps lead your eye towards the spectacular awe-inspiring bedroom.

The ensuite contains a stunning huge acrylic window that runs the full length of the room (4.8m x 1.9m x 180mm thick).

Even the walk-in wardrobe has a window looking out to the fishes.

Because the UWV has a shower, toilet and vanity, there was special need to incorporate a sealed ventilated service room, complete with sewage tank and submersible pumps - and of course all whilst incorporating emergency alarms for added security.

All windows are designed to safely withstand a tsunami or freak wave.

Acrylic Installation Photos

All windows were manufactured in Japan by Nippura Co., and sealed with special silicone sealant - Shin Etsu Marine sealant, and cured for minimum 14 days.

Transporting to crane ship - early February 2018

After the sealant had cured, and after the upper entry building had been erected over the stairwell, the entire structure was packaged, protected and waterproofed for the journey to the Maldives. The temporary shelter was removed, and the UWV was lashed to the barge.

Preparing the UWV for journey to the crane ship.

Then, with the guidance of 2 tugboats, the UWV barge was pushed-pulled on a 4 hour journey to the agreed wharf in Singapore to meet with the jumbo crane ship "The Fairlane" (this was the same ship used for our Huravalhi underwater restaurant).

2 tugboats taking the barge to the crane ship.

Considerable early work was done by Jumbo, the client, and M.J. Murphy Ltd to ensure that The Fairlane could safely moor at the Maldives site, without hitting the coral reefs, and still lift the UWV out over the 10 waiting piles.

The Fairlane being pushed against the UWV barge.

Singapore - lifting the UWV onto the crane ship

Picture one: tense moment - the first big lift of the UWV (610 tonnes).

Picture two: Mike Murphy giving the 2 cranes a "helping hand".

Some proud members of the team in Singapore. Hong Hock Engineering, M.J. Murphy, Shenaz Trading, Jumbo.

Arrival in the Maldives - mid-February 2018

The Fairlane arrives at Rangali island, ready to offload the UWV into the water.

The concrete jetty and platform for the over-water villa were built in readiness to receive the UWV.

14th February 2018

Starting the "big lift" into the water. Slow and careful, as the ship had to be constantly stabilised as the load reached further out.

The UWV almost in the water, alongside the concrete platform upon which the luxury over water villa will soon be built, and joined to the UWV.

Sinking the UW Villa

The UWV half-submerged in the water. Divers guided the pile legs into the 10 big steel piles, using microphones and underwater cameras - liaising directly with the ship's captain.

DOWN!

The UWV now completely down on the piles, with sufficient residual dead load to prevent the UWV from floating at high tide, until the legs were concreted in place - again using divers and concrete pump.

Client - Architect Saleem had the honour of being

the first to go inside the UWV after the sinking.

After the sinking

15th February 2018

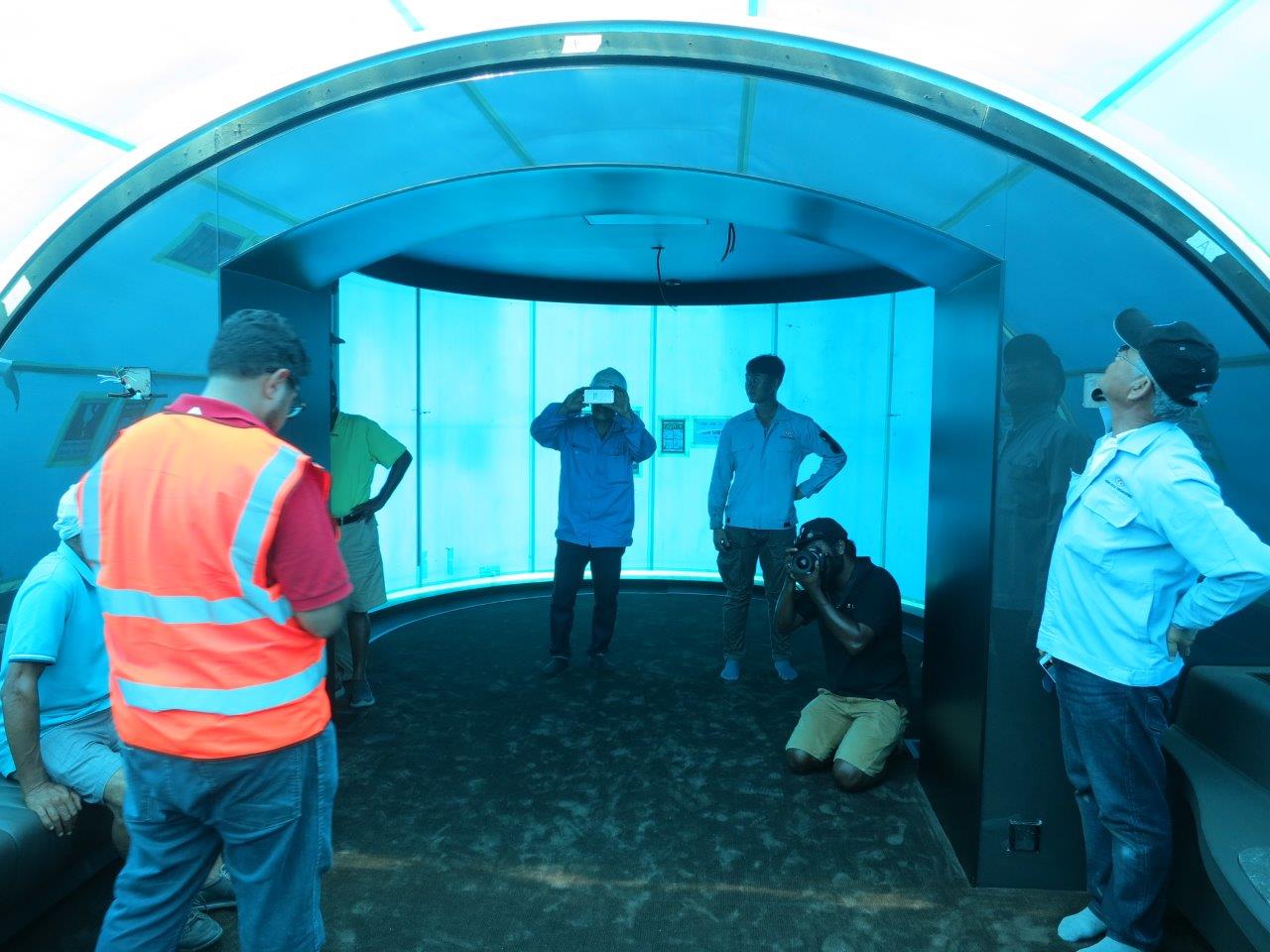

Staff and clients inspecting the inside of the UWV immediately after the sinking.

Checking for signs of leakage or damage (happily no problems).

Note the protective blue plastic sheeting is still attached to the acrylic windows.

Carpet and tiles were laid in Singapore. The bed and other furnishings later installed in Maldives.

Inspecting the panoramic lounge window after sinking. All OK.

Blue plastic protection still on the window.

16th February 2018

Local project manager Suhaul Ahmed overseeing installation of the bed and mattress.

Mike Murphy's feeble attempt to be the first to "sleep" on the bed.

The official honour will likely go to client Ahmed Saleem.

Mike Murphy (right), and Jumbo Captain Peter Mathot celebrating the successful sinking, by dining in the famed underwater restaurant Ithaa (built in 2004).

- see link to Ithaa

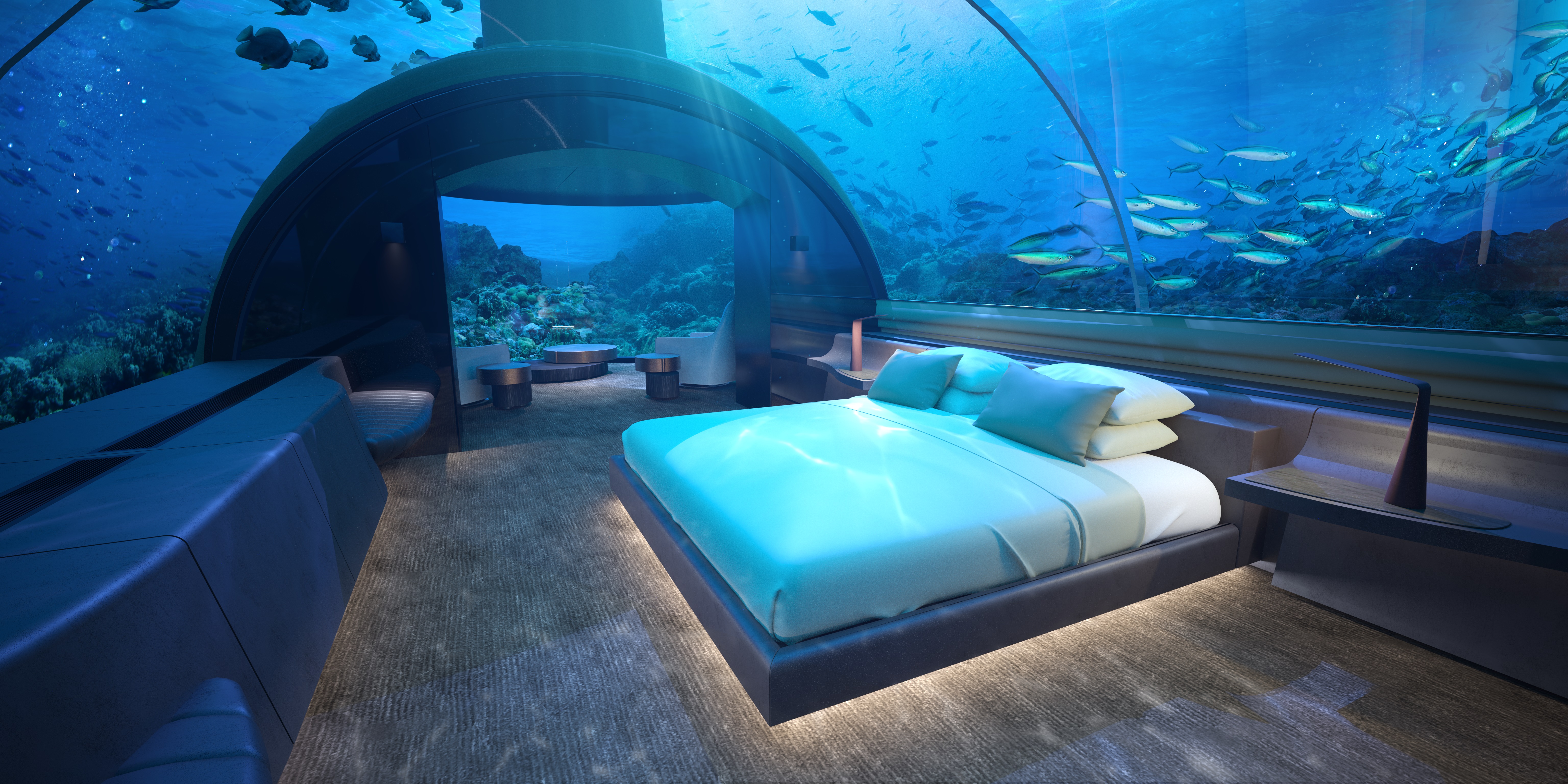

Conrad Underwater Villa

Spectacular view of the finished underwater bedroom, with lounge in the background - Photo courtesy of Conrad Hilton

Sunset over Ithaa UWR - very near to the new UW Villa.

SUMMARY

The Underwater Villa project has been a great success - and a huge team effort by many enthusiastic and talented people. M.J. Murphy Ltd are very proud and grateful to Crown Company and Conrad Hilton, for allowing us the honour of designing this very special project, and special thanks to Hong Hock Engineering for their ingenuity and dedication.

The UWV is now called "Muraka", meaning coral. It is targeted for official opening in November 2018.