THE SINKING OF HURAVALHI

UNDERWATER RESTAURANT

MARCH 2016

New underwater restaurant (UWR) for

Huravalhi Island Resort, The Maldives, for clients

Champalars Holdings (PVT) Ltd.

This UWR has become the largest and most spectacular

UWR yet built in the world.

UWR Designers: - M.J. Murphy Ltd, Auckland, NZ

Main Contractors (NZ): - Fitzroy Engineering Ltd, New Plymouth, NZ

Acrylic Contractors: - Nippura Co, Japan

Air Conditioning Consultants: - Jackson Engineering Advisers Ltd, Auckland, NZ

Interior Design: - Stuart McKechnie Architects Ltd, Auckland, NZ

Fire Engineers:- Origin Fire Consultants Ltd, Auckland, NZ

Electrical Consultants:- LHT Design, Hastings, NZ

Piling Contractor: - Heavy Force PVT Ltd, Maldives

Concrete Contractor: - M.T. Højgaard Ltd, Maldives

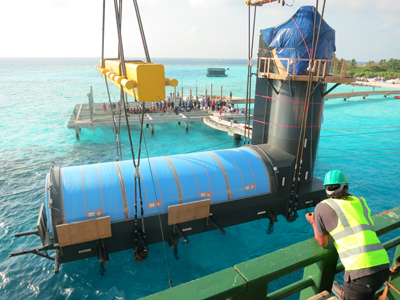

HURAVALHI ISLAND - On 3 March 2016, after a journey of 3 weeks from New Plymouth in New Zealand, the giant crane ship the 'MV Fairlane' berthed at Huravalhi Island, and slowly lifted our newest and largest UWR into the sea, and down on to 8 large diameter steel piles, alongside a beautiful coral reef. An exciting day!

NEW PLYMOUTH, New Zealand, February 2016 - Over the evening of 9th February, the latest big fabrication project to come out of Fitzroy Engineering made its way slowly to Port Taranaki. Following the usual 8km route from Fitzroy's factory to the port, the 410 tonne Underwater Restaurant was manoeuvred alongside the giant crane ship "The Fairlane", using 3 trucks. Then on 11 Feb, two giant 400 tonne capacity cranes lifted the UWR onto the ship and readied it for its 3 week trip to the Maldives.

Designed by MJ Murphy Ltd, this underwater restaurant (UWR) will be the second only of its type to be deployed anywhere in the world. MJ Murphy Ltd were also the designers of the first UWR (now world famous, called Ithaa... also in the Maldives for a different resort Conrad Hilton - see here).

This new UWR was delivered to site in early March 2016 and lowered onto specially prepared piled foundations on the edge of a beautiful coral reef at Huravalhi Island in the Maldives, where the clients, Champalars Holdings Pvt Ltd are building a complete new luxury 5 star resort.

As many scuba divers will attest, the water in the Maldives is especially clear and the corals and fish life astounding. The UWR will sit alongside the steeply descending coral reef, so that all diners can view the corals and the fish they attract. For the deep open ocean side, special concrete platforms have been developed by MJ Murphy upon which the corals from under the UWR have been replanted, and are now waiting in the sea for the arrival of the UWR. These ‘coral garden’ platforms will be lifted off the seabed and bolted to the ocean-side of the UWR once in place, so that diners on the ocean side also get an amazing view of corals and attracted fish life.

“The amazing 5m wide x 130mm thick acrylic arches covering the UWR have been designed by M.J. Murphy Ltd and fabricated in Japan, by world renowned acrylic company Nippura Co. The acrylic is optically perfect, so diners will feel ‘immersed’ and surrounded by the ocean and the fish life. There will also be a large spectacular panoramic underwater acrylic window (190mm thick) in the end wall of the UWR which is expected to wow the lucky diners, with amazing long views along the sloping coral reef.

The underwater dining room is accessed by foot down an impressive spiral staircase at one end, beautifully timber lined and complete with two smaller underwater acrylic windows to titivate the patrons as they descend down to the dining room, glass of sparkly wine in hand. There will also be a dumb waiter lift for restaurant staff to bring down all food and drinks from the above-water kitchen, and there is a small kitchen - lobby at the bottom, where waiters can prepare food and drinks, ready to serve.

The underwater dining room is accessed by foot down an impressive spiral staircase at one end, beautifully timber lined and complete with two smaller underwater acrylic windows to titivate the patrons as they descend down to the dining room, glass of sparkly wine in hand. There will also be a dumb waiter lift for restaurant staff to bring down all food and drinks from the above-water kitchen, and there is a small kitchen - lobby at the bottom, where waiters can prepare food and drinks, ready to serve.

Fitzroy Engineering were successful in securing this project in the face of strong international competition, and their ability to fund and coordinate large work-scopes allowed them to manage the bulk of the work required. This included all of the steel fabrication, installation of the acrylic windows and roof, ballasting, installation of air conditioning fire proofing, and electrical systems and all of the internal fit out.

The restaurant is 18m long x 5.4m wide, and working with MJ Murphy Ltd, Fitzroy established that considerable efficiencies could be achieved by building the floor of the hull from 114mm thick steel in order to add very efficient ballast weight. Procedures to heat, weld and safely rotate the 80 tonne floor were developed and implemented and this proved to be very successful.

With the ability of "The Fairlane" to be able to lift well over 400 tonnes, this enabled us to load all the extra ballast weight (concrete and gravel-sand) into the belly of the UWR before it left NZ. This had a huge advantage, as it meant we did not have to add further ballast on site (to sink the UWR) which would have delayed the ship on site for a further few days (at great expense), and at the risk of worsening weather.

One of the most exciting periods (and most worrying for the Captain of "The Fairlane") was when the Captain guided his huge 110m long ship through the narrow channels between coral reefs, to finally moor at the UWR site. 2 tugboats were required to guide the ship and keep it off the reefs.

One of the most exciting periods (and most worrying for the Captain of "The Fairlane") was when the Captain guided his huge 110m long ship through the narrow channels between coral reefs, to finally moor at the UWR site. 2 tugboats were required to guide the ship and keep it off the reefs.

Actions and decisions were also affected by the overly strong winds which typically increased during the afternoon. Finally, after a long day, the ship reversed in alongside the 8 piles for the UWR, and many mooring lines were run out. The tugboats were always held on standby, in case of bad weather.

Huge assistance in all shipping and lifting matters was given by JUMBO Shipping, and shipping logistics company GAC (with branches worldwide). We certainly learnt a lot from their experience.

Due to the increasing winds, it was decided to postpone the "big lift" until the next morning when the winds were expected to be typically quieter.

THE BIG LIFT

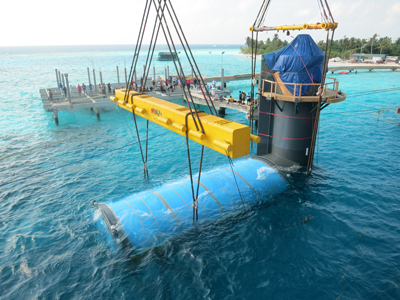

Then on 3 March 2016, after the removal of all lashing cables, and preparing all UWR legs for connection to the undersea piles, the UWR was slowly lifted off the ship's deck and lowered carefully into the water.

Commercial divers were employed to help guide the UWR legs into the waiting piles. Underwater cameras also assisted the Captain in guiding his 2 huge cranes.

GOING...

GOING...

GONE!

Efficient quick communication with the divers was found to be crucial, and lessons were learnt on how to improve on this for the next project.

The UWR was designed to have around 40 tonnes of additional ballast weight, so that it could be safely landed on the piles, without floating away. Additional hand winches were also fixed to give extra 'peace of mind', until concrete could be poured into the piles (by divers), and hence locking the UWR securely in place.

After "The Fairlane" left the site, the clients employed a local piling and concrete contractor (M.T. Højgaard Ltd), with a concrete pump, mixer and crane on a barge, to pump concrete into all 8 steel piles, (tremie method), with the aid of commercial divers. Our thanks to Heavy Force for their skill in accurately driving the piles, to within our required tolerances and to M.T. Højgaard for their challenging concrete works.

Once the UWR was secured to the piles, and crane cables removed, our Client Lars Petre was the first person to enter the UWR to inspect the interior, followed by ourselves and other local personnel and TV news camera crew. Very exciting occasion for all! On first inspection, all looked perfect! No leaks, and no damage. Everyone was very pleased.

The protective plastic film was left in place on both sides of the acrylic until all concrete works and interior works were done...then removed to reveal the full amazing vista of the coral reef, teeming with fish. A week after the sinking, three large concrete slabs (with corals already starting to grow on them) were carefully lifted onto the steel outriggers waiting on the ocean side of the UWR. Then over the coming months (and longer), Clients' divers will artfully place various corals on them to create a new 'coral garden' to attract fish to all sides of the UWR.

Above: HURAVALHI ISLAND RESORT, X marks the location of the Underwater Restaurant

SUMMARY

The Underwater Restaurant project for Huravalhi Island has been a great success, and a very exciting project for all parties involved. M.J. Murphy Ltd are very proud and grateful to the clients, Champalars Holdings (PVT) Ltd for allowing us the honour of designing their dream project. And special thanks to Fitzroy Engineering.

THE UWR WAS OFFICIALLY OPENED IN DECEMBER 2016, AND HAS BEEN CALLED “5.8” (signifying 5.8m under the sea). The Clients are very happy, and the restaurant has already received rave reviews. You must go and visit!

See link… http://www.hurawalhi.com/dining/undersea-restaurant/